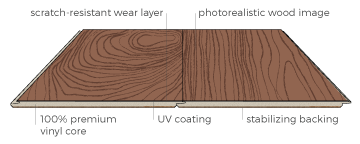

This top layer of pure vinyl is called the wear layer and is the most expensive part of the flooring since it is the only thing protecting the paper print film.

What is considered a sufficient wear layer on vinyl lvp.

As you may have guessed the thicker the wear layer the tougher the flooring will be.

It effects how well the wear layer bonds to the surface of the vinyl.

While the internet has certainly become a huge research tool for consumers to educate themselves for making a purchase many companies still do not provide full technical specs that are easily available for a consumer to find.

Wear layer lvt has a transparent wear layer on top of the printed design layer to protect it and the wear layer of lvt plays a large part in determining the lifetime of the tiles.

The most popular is a urethane based layer that protects the floor against scratches stains and scuff marks.

The wear layer keeps the original look of the floor longer providing a maintenance free finish.

Minimum of 6mm for high traffic read the warrantee carefully.

Wear layer is the thickness of the top protective layer minimum of 12 mil or 20 mil for pets and young children floor thickness is the total thickness of the floor minimum of 3mm for low traffic areas.

Different manufacturers have different standard thicknesses for the wear layers on their lvt products.

This means that a significant portion of maintenance time and effort is spent applying and polishing a wax coating which requires periodic stripping and reapplication to protect your flooring from scuffs scratches and stains.

Better vinyl floors have wear layers that include a protective top coat.

In short the thicker the wear layer the more durable the floor.

Vinyl composite tiles don t have a wearlayer.

If you have a space that will need a high resistance to scratches and wear a higher wear layer such as a 12 mil or 20 mil would be best for your application.

The thickness of the wear layer is measured in mils and wear layers are typically 6 12 or 20 mils thick.

The wear layer is the protective coating on top of the decorative layer of the vinyl flooring.

Commercial vinyl flooring applications will usually require a 20 mil top layer.

During manufacturing these substances need to bond to the flooring through the process of curation.

Higher quality products have the best warrantees.

.jpg)