The ceramic capacitor is made by making a finely grounded powder of a dielectric material which is either paraelectric material like the titanium.

What is a ceramic capacitor made of.

Ceramic disc capacitors have a capacitance value of about10pf to 100μf with a wide variety of voltage ratings between 16v to 15 kv and more.

Characteristics precision and tolerances.

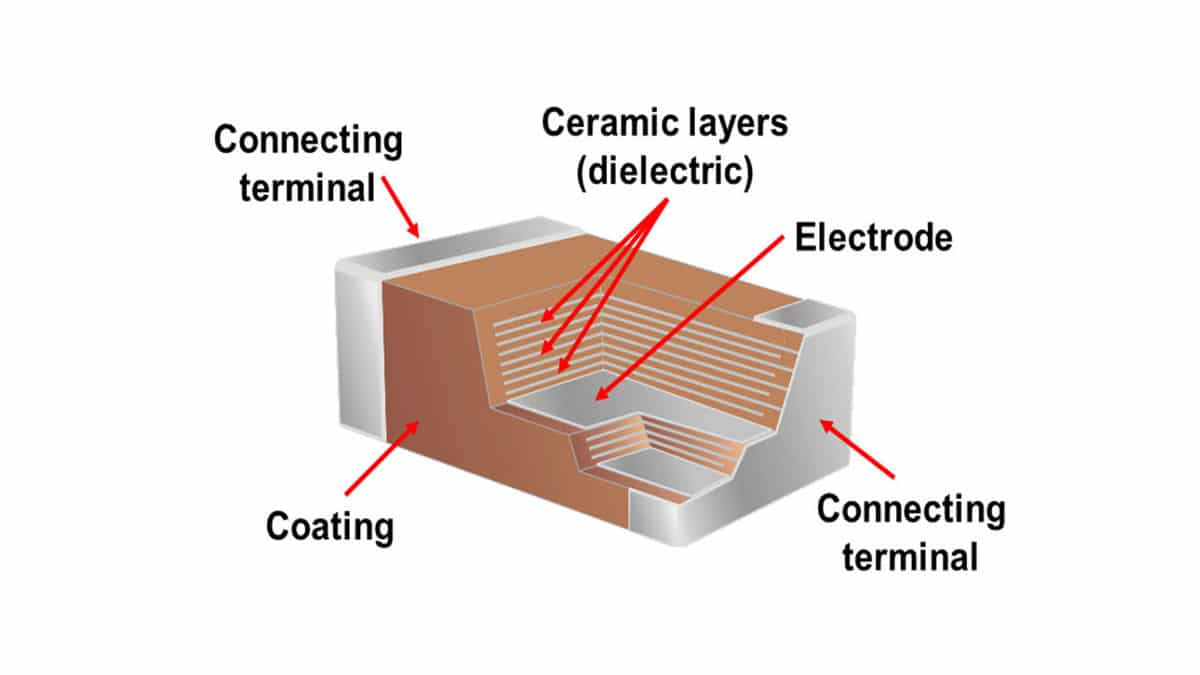

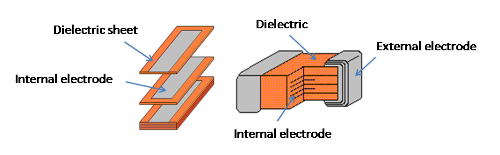

A ceramic capacitor is a fixed value capacitor where the ceramic material acts as the dielectric it is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes the composition of the ceramic material defines the electrical behavior and therefore applications.

A capacitor consists of two conductors separated by a non conductive region.

The thickness of the sheet determines the voltage rating of the capacitor.

The capacitors in which the ceramic material such a paralectric titanium oxide or ferroelectic is used as the insulating material or dielectric is known as the ceramic capacitors.

Different types of ceramic capacitors.

From coulomb s law a charge on one conductor will exert a.

Ceramic disc capacitors are made by coating a ceramic disc with silver contacts on both sides as shown above illustrates.

Ceramic capacitor definition a ceramic capacitor is a capacitor which uses a ceramic material as the dielectric.

Ceramic capacitors are classified as type i type ii or type iii.

They have high insulation resistance and lower frequency losses and maintain a stable capacity even when voltage varies.

The non conductive region can either be a vacuum or an electrical insulator material known as a dielectric examples of dielectric media are glass air paper plastic ceramic and even a semiconductor depletion region chemically identical to the conductors.

These are used in resonant circuits filters and.

There are two classes of ceramic capacitors available today.

Class 1 and class 2.

The two most common types are multi layer ceramic capacitors and ceramic disc capacitors.

Screen printing and stacking.